Custom Woven Patches Los Angeles – High Definition Detail

Complex logo? Tiny text? Embroidery can’t handle it. Woven patches use micro-threads to capture every pixel. Get the “4K Resolution” look for your brand; flat, lightweight, and retail-ready.

- Ultra-High Resolution: Clean text down to 2mm.

- Zero Bulk: Smooth, flat surface ideal for sportswear.

- LA Ready: The standard for DTLA Fashion & Silicon Beach Tech.

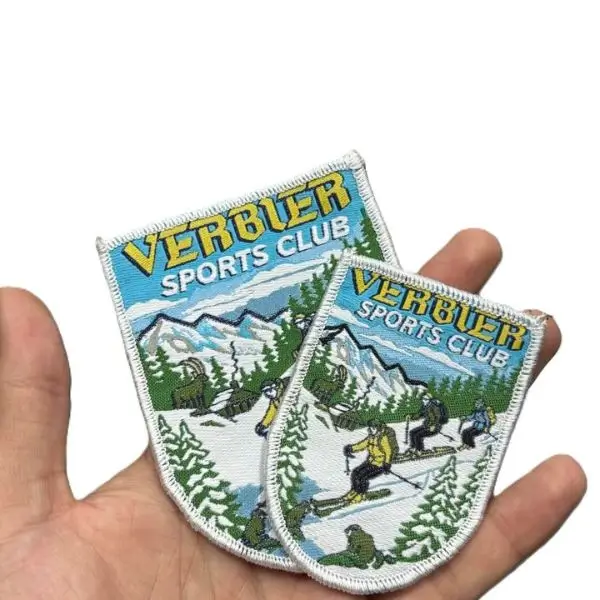

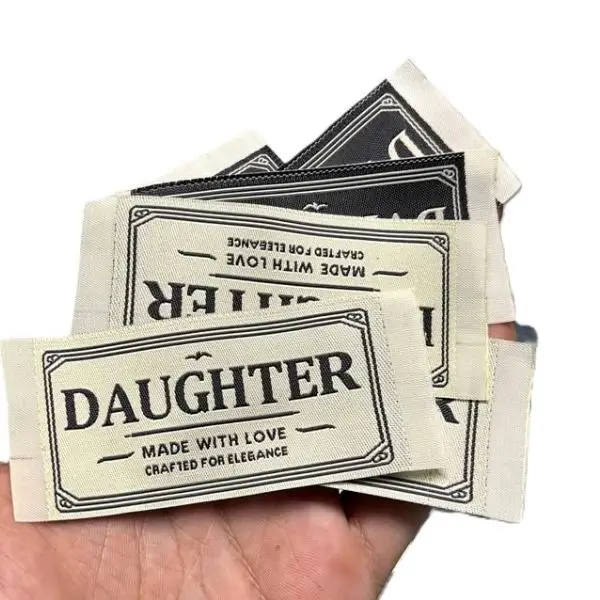

Recent Projects

Check out our latest factory runs: high-definition woven patches for sports clubs and crisp branding labels for LA fashion lines. We capture micro-details from tiny skiers to bold typography, that standard embroidery just can’t touch. Whether it’s tactical Velcro backings or delicate hem tags, we engineer every piece to retail standards.

The Solution for Complex Logos and Fine Text

We see it every day. A client sends us a logo with a phone number or a slogan packed inside a 3-inch circle. We have to be honest: “If we embroider this, that text will look like a blob.”

Why Woven? (The “HD Resolution” of Patches)

We use a much thinner thread (called high-denier thread) for woven patches. This allows us to pack more detail into a smaller space. You get clean lines, sharp corners, and a flat profile that doesn’t snag.

Perfect for Text Under 3mm (Where Embroidery Fails)

Embroidery struggles with anything smaller than 4mm. The needle is just too wide. Woven patches can handle text as small as 2mm. If your design has legal disclaimers, tiny stars, or intricate maps, woven is the only choice.

Lightweight & Flexible (Ideal for Sportswear)

Embroidery adds stiffness. If you put a heavy embroidered patch on a thin soccer jersey or a performance fishing shirt, it weighs the fabric down. Woven patches are featherlight. They move with the garment, not against it.

Border Options: The Finishing Touch

Merrowed Border (The Classic Patch Look)

We take a thick overlock stitch and wrap it around the edge of the patch. This gives it a “frame.” It makes a woven patch look like a traditional embroidered patch. This is the most common choice for iron-on patches.

Laser Cut Border (For Custom Shapes)

If your design is a complex shape like a dragon or a jagged lightning bolt, we use a laser to cut the patch out. The laser heat-seals the edges to prevent fraying. This creates a modern, “floating” look with no heavy border.

Detailed Backing Guide for Woven Patches

Because woven patches are thinner than embroidery, the backing is what gives them their “body” and stiffness.

Iron-On (Heat Seal)

Peel & Stick (Adhesive)

Sew-On Backing

Serving Los Angeles Industries

DTLA Fashion District: Neck Labels & Hem Tags

We work with the brands cutting and sewing right here in the Fashion District. Whether you need inside neck labels that don’t scratch or hem tags for that high-end branding on a hoodie, we weave them to retail standards.

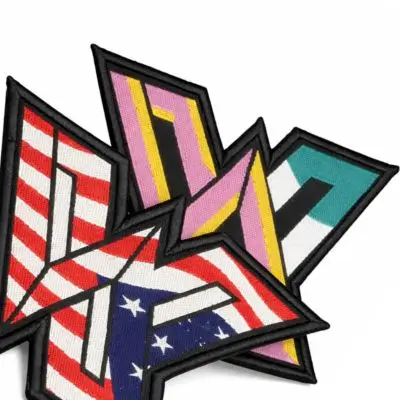

Silicon Beach: High-Detail Tech Company Swag

Tech logos love gradients. They love complex geometry. Startups in Silicon Beach and Culver City use our woven patches for laptop bags and hoodies because we can actually replicate their app icons perfectly.

Hollywood Production: Costume Department Replicas

When a prop master needs a patch that looks 20 years old or needs a specific government seal with tiny text, they call us. We can match the matte finish and flat look required for camera close-ups.

Serving Los Angeles Industries

| Industry | Details |

|---|---|

DTLA Fashion District: Neck Labels & Hem TagsWe work with the brands cutting and sewing right here in the Fashion District. Whether you need inside neck labels that don’t scratch or hem tags for that high-end branding on a hoodie, we weave them to retail standards. |

|

Silicon Beach: High-Detail Tech Company SwagTech logos love gradients. They love complex geometry. Startups in Silicon Beach and Culver City use our woven patches for laptop bags and hoodies because we can actually replicate their app icons perfectly. |

|

Hollywood Production: Costume Department ReplicasWhen a prop master needs a patch that looks 20 years old or needs a specific government seal with tiny text, they call us. We can match the matte finish and flat look required for camera close-ups. |

3-Step Production Process

-

1

Vector Art Submission

Send us your AI or PDF file. We need vector art to get the weaving loom set up correctly.

-

2

High-Res Digital Proof

We send you a mock-up showing exactly how the threads will map out. You confirm the colors and spelling.

-

3

Weaving & Fast Shipping

Once approved, we weave the batch. Shipping to Los Angeles addresses usually takes 2-3 days once production clears quality control.

Get a Free Woven Patch Quote

Got a complex design? Don’t dumb it down. Weave it. Send us your art today for a price quote.

Get a Free QuoteThe Technical Guide to Manufacturing Woven Patches

Most people just order “patches” without knowing how they get made. If you want the best result, you need to understand the mechanics. Here is how we build a woven patch from scratch.

What is a Woven Patch? (Loom vs. Needle)

Here is the difference in plain English:

Embroidery takes a piece of fabric (twill) and uses a needle to stitch a design on top of it. It adds height.

Woven creates the fabric and the design at the same time. We use a loom to interlace vertical threads (warp) and horizontal threads (weft).

Because we aren’t stitching on top of a base layer, there are no gaps. The surface is completely uniform. This is why woven patches feel like smooth fabric rather than a bumpy relief map.

Material Specs: Understanding “Damask” Weave

Not all woven patches are the same. If you don’t specify the weave, some shops will sell you low-grade polyester. At Los Angeles Patch Co., our standard is Damask.

What is Damask? (100 Denier Tight Weave)

Damask is the industry standard for high-end branding. It uses 100 Denier thread, which is extremely fine and strong. It creates a tight, opaque weave with a matte finish. It feels soft to the touch but looks incredibly sharp. If you are a clothing brand, you want Damask.

Satin Weave (For Shiny/Glossy Finish)

Satin weave uses a different thread structure that reflects light. It makes the patch look shiny or glossy.

Taffeta Weave (The Budget Option)

This is a loose weave. You can sometimes see the background threads showing through the design colors. We rarely use this for external patches. It’s mostly used for the bottom side of care labels, where no one looks.

Woven Patches vs. Woven Labels: What’s the Difference?

Terminology matters.

Woven Patches

Have a stiff backing and a finished edge (Merrowed or Laser Cut). They are meant to go on the outside of a sleeve, hat, or bag.

Woven Labels

Have NO backing. They are soft and floppy. They are meant to be sewn into the neck or the hem of a shirt. If you want neck tags, ask for “Labels,” not “Patches.”

Frequently Asked Questions (Woven)

Style & Finish

Can I mix Woven and Embroidery?

Yes. This is called a “Woven Patch with Merrowed Border.” The center is woven (for that high-detail HD look), but we use an embroidery machine to stitch a thick overlock border around the edge. It gives you the best of both worlds: high detail in the middle, classic heavy patch feel on the edge.

Do woven patches look pixelated?

No. They look sharp. However, because they are built on a grid (warp and weft), curved lines are technically made of tiny steps. But because the thread is so fine (100 Denier), the human eye sees a smooth curve. It’s cleaner than embroidery, which often looks “jagged” on small text.

Technical Details

What is the minimum text size for woven?

2mm. We can go slightly smaller if the font is blocky (sans-serif), but 2mm is the safe zone for legibility.

How do I prevent woven patches from fraying?

If you choose a Laser Cut Border, the laser melts the polyester threads as it cuts, sealing the edge instantly. It will never fray. If you cut a woven patch with scissors yourself? It will unravel immediately. Don’t do that. Let us cut it to size.