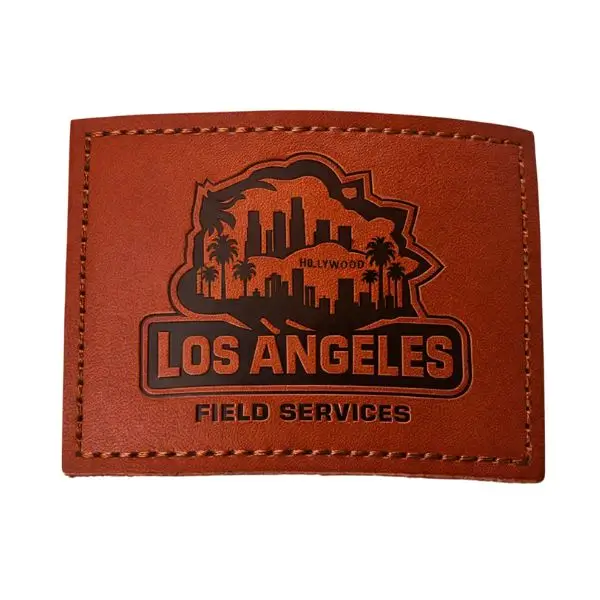

Custom Leather Patches Los Angeles

Smell that? That’s vegetable-tanned cowhide. You can’t fake that scent with plastic. Leather hits different. It’s not about bright colors or high-resolution threads. It’s about texture. It’s about the burn marks from the laser and the way the material ages when you wear it out in the sun.

- Whether you need 50 patches for a whiskey bar in Silver Lake

- or 5,000 faux leather labels for a denim run in the Fashion District

- we handle it right here. We cut the hide, we burn the logo, and we prep the backing.

Recent Projects

Our latest collection of heat-debossed and engraved leather branding. From rugged, high-contrast patches for service crews to delicate hem tags for retail lines, notice the sharp, dark burn against the natural grain. From heavy-duty hat patches for local contractors to intricate branding labels for boutique pet brands, every piece features clean lines and that authentic leather smell.

Premium Branding for Hats, Denim, and Apparel

Leather is the heavy lifter of branding. You slap a leather patch on a Richardson 112, and it instantly doubles the retail value. It turns a generic promotional cap into merchandise people actually want to buy.

We see a lot of cheap, thin leather out there. It curls up like a potato chip after one wash. We don’t use that scrap. We use thick, proper grades that stay flat and hold the logo.

Material Options: Real Hide vs. Vegan Leather

Genuine Leather: Vegetable-Tanned & Rugged

- The Look:

- Natural, inconsistent, and rugged.

- The Aging:

- It develops a patina. It gets darker and softer the more you handle it.

- The Warning:

- It’s skin. No two patches look exactly 100% alike. That’s the point.

Faux Leather (Leatherette): Waterproof & Uniform Color

- The Look:

- Perfectly consistent color. Every patch looks identical.

- The Benefit:

- It’s hydrophobic. Sweat, rain, and saltwater won’t stain it.

- The L.A. Advice:

- If you’re outfitting a crew at the Port of LA, go with Faux. Real leather rots in salt air; this survives.

Logo Styles: Debossed, Laser Etched, or Printed

Heat Debossed

The Classic ‘Burned’ LookWe mill a solid brass die of your logo. We heat it to 300°F+ and press it into the leather with hydraulic pressure.

Laser Engraved

Precision Detail for Complex ArtWe use a CO2 laser to vaporize the top layer of the hide.

UV Printed

Full Color on LeatherWe use a flatbed UV printer to blast ink directly onto the surface. It bonds tight to the fibers.

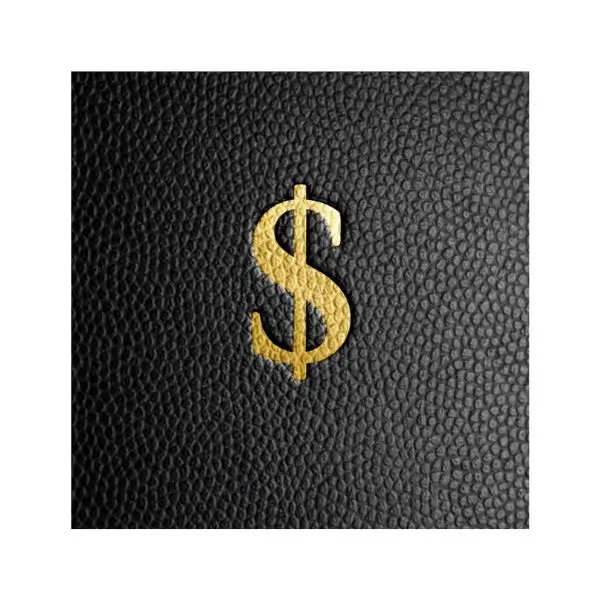

Foil Stamping

Metallic Gold or Silver FinishWe sandwich a layer of metallic foil between the hot brass die and the leather. It presses the gold into the grain.

Popular Applications in Los Angeles

Richardson 112 Hat Patches

The trucker hat standard. We size these specifically to fit the front panel profile. We recommend a slightly thinner leather here so it curves with the crown.

- Standard Size: 2.25″ x 4.5″

- Best Material: Flexible Faux or Thin Cowhide

- Placement: Front Center or Side Panel

Custom Jeans & Waistband Labels

We manufacture thick, wash-tested leather labels for the denim houses downtown. We usually pre-punch the stitch holes so your sewing machines don’t jam.

- Standard Size: 2.5″ x 3.25″

- Best Material: Heavyweight Vegetable-Tanned Hide

- Pro Feature: Pre-punched ‘Stitch Channels’ included

Beanie & Knitwear Branding

Leather on a beanie adds perceived value. We use a ‘sandwich’ label or a center stamp. Faux leather is better here for laundry reasons.

- Standard Size: 1.5″ x 1.5″ or Fold-over

- Best Material: Faux Leather (Washable)

- Recommendation: Center-front cuff placement

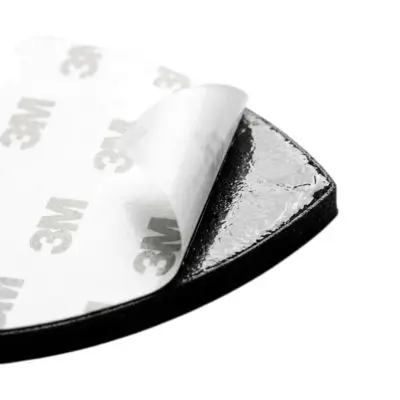

Backing Options: How to Attach Them

Heat Seal (Iron-On)

Velcro (Hook & Loop)

Sew-On: Stitch Groove

The “Sweat Stain” Rule

“If you’re making hats for a landscaping crew or a gym, do not use real leather. Real leather absorbs sweat. Over time, that patch will turn dark, shrink, and stain the fabric of the hat.”– Head of Production, Los Angeles Factory

Get a Quote for Leather Patches

Don’t overthink it. Send us your art. We’ll tell you if it works better as a Hot Stamp or a Laser Etch.

Request Quote NowManufacturing Specs & Leather Types

Let’s get under the hood. Most people think “Leather is Leather.” Wrong. There are layers to the hide, and picking the wrong one means your patch falls apart in six months.

Genuine Leather Grades Explained

We don’t use “Bonded Leather” (which is basically leather dust glued together). We deal in whole hides.

Full Grain: Maximum Durability & Character

This is the top layer of the hide. It hasn’t been sanded down. You might see natural imperfections a pore, a scar, a wrinkle. That’s not a defect; it’s proof. It’s the strongest grade available. It absorbs oil and sun, getting darker and better looking with age.

Top Grain: Sanded & Smooth

We take the top layer and sand off the imperfections. It’s thinner and more pliable than Full Grain. If you need a patch to curve around a tight radius (like a small beanie cuff), Top Grain is often the better engineering choice.

Vegetable Tanning vs. Chrome Tanning

This matters for burning.

Veg-Tan: Tanned using tree bark and tannins. It’s stiff. It reacts beautifully to heat (burns dark). This is what we use for patches.

Chrome-Tan: Tanned using chromium salts. It’s soft and gray-blue in the middle. It does not burn well (it melts/chars). If a supplier sells you soft, floppy leather patches, they are using cheap upholstery scrap. Avoid it.

The Difference Between Debossing and Laser Engraving

Clients confuse these. Here is the physics.

We mill a brass die. We heat it up. We use hydraulic pressure to physically compress the leather fibers. The result is a 3D valley. The heat draws the natural oils to the surface, darkening the logo.

A laser beam shoots the surface. It vaporizes the top micron of leather. It creates high contrast (burnt dark brown vs. light tan leather). It is flat. It allows for gradients (using dot patterns) that a stamp can’t do.

Leather Selection & Care Guide

Why Choose Vegan (Faux) Leather?

Don’t think of it as “cheap.” Think of it as “engineered.”

Real leather is a sponge. It absorbs water, sweat, and oil. If you wear a real leather patch on a 5-mile run in the Santa Monica heat, it will soak up sweat, turn dark, and eventually dry out and crack.

Faux Leather (Leatherette) is hydrophobic. It repels water. It wipes clean. It looks exactly the same on Day 1 as it does on Day 1,000. For high-use workwear, Faux is the superior material.

Comparing Leather vs. Embroidered Patches

Your logo is simple. You want a high-end, retail aesthetic. You care about texture.

You need specific brand colors (Coke Red, Best Buy Blue). Leather is brown. You can’t dye a laser burn. Also, if your design has 50 different elements, leather will look muddy. The thread holds tiny details better than a stamp.

Care Instructions for Leather Patches

Real Leather:

NO Machine Wash. Hot water and soap strip the oils. The patch will shrink and pull at the stitching on your hat.

Clean: Wipe with a damp cloth. Use leather conditioner once a year if it looks dry.

Faux Leather:

Wash: Hand washing is best. Machine wash cold if necessary. Air dry. It won’t shrink.

Frequently Asked Questions ( Leather Patches)

Design & Color

What creates the dark color on the logo?

We don’t add ink. The “ink” is the carbonized leather itself. The heat of the laser or the stamp burns the natural sugars and tannins in the hide, turning it dark brown or black.

Shapes & Sizes

Can you make custom shapes?

Yes. We laser-cut the perimeter. We aren’t limited to circles and squares. If you want the patch in the shape of the State of California, we cut the outline with the laser. It seals the edge instantly.

Setup Fees

Is there a setup fee for the brass mold?

Only for Debossing. If you want the deep 3D stamp, we have to CNC mill a physical piece of brass. That costs money. If you choose Laser Engraving, there is no mold fee because it’s just a digital file.